Which waterproofing membrane is suitable, torch on membrane vs liquid applied membrane?

The most frequently asked questions by most home owners “what is the best waterproofing membrane for their property? Would it be torch on bitumen membrane or liquid applied membrane?” Not only asked by home owners, it’s been a long time question asked by the professionals such architects, engineers and even building contractors. Each of these membrane have their own benefits, but what are the important aspects that determine its application.

The benefits of torch on bitumen waterproofing membrane:-

Torch on bitumen sheet waterproofing membrane is popular among applicators for its strength and more solid membrane base that is created to shield the exterior from dampness and water.

- Easily suite various kinds of flat roof materials , can be used to protect car park decks, green roofing, deck bridge and others.

- Have great resistance towards various weather conditions.

- Bitumen membranes often have high life expectation, even throughout the age it will able to maintain its flexibility and elasticity hence known as the perfect solution for flat roofs.

- Exceptional bond to the substrate on a flat roof installation

- In most general situation where the bitumen membrane system nearing to its life span, a new bitumen sheet can be overlay to install it over the previous system to extend the life service of the system.

Waterproof membrane comes in liquid form, which can be applied with various method such as roller, brush or spray. The liquid will require some time to cure to a solid membrane. After the liquid membrane is applied on the surface it will dries off after a period of time to form a flexible and blocked membrane which protects the screed from water.

The benefits of using liquid membrane

- Seamless application and can be cold applied.

- Can use various application method, using spray gun will increase the speed and also consistency

- UV resistance

- Have high elasticity

- Available in different colours depending on the manufacturer.

The method of bitumen torch-on waterproofing is utilized in construction to creäte a watertight barrier on a flat roof or low sloped. This method involves utilizing modified bitumen sheets that are fixed to the surface using a propane torch, where the bitumen is melted by the heat to bond with the surface and create a waterproof barrier. It is a widely used practice in both commercial and residential construction to protect surfaces such as roofs and decks against water penetration. This method requires a professional waterproofing contractor with skill in torch-on roofing performs this process.

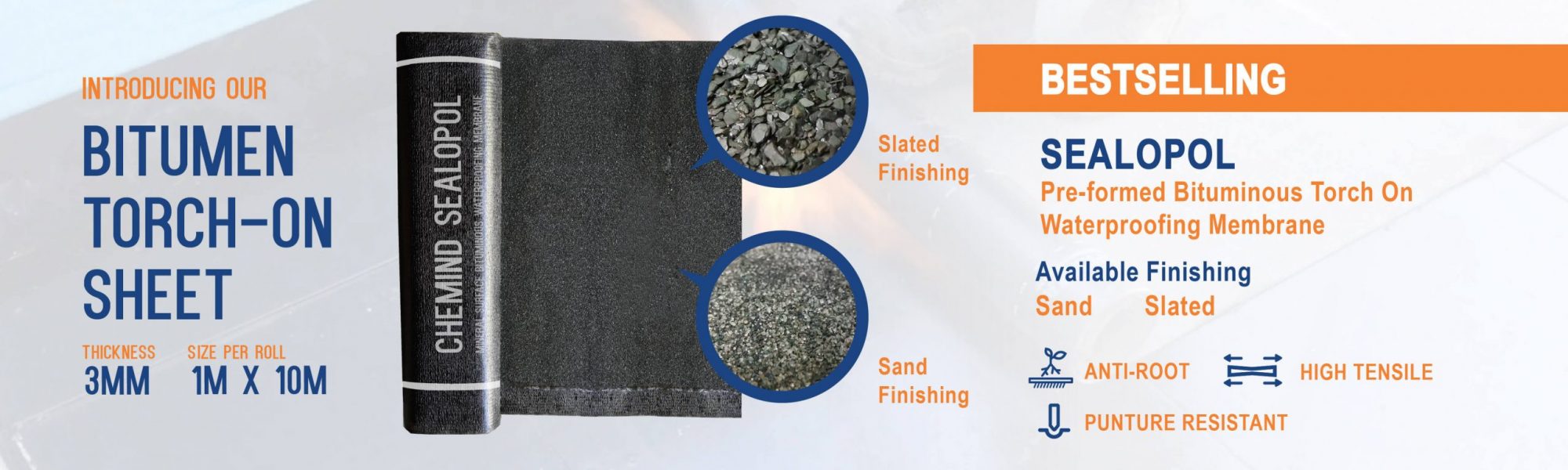

Introducing Chemind Industries’ Sealopol – a high performance polymer modified plastomeric bituminous waterproofing membrane, surfaced with reflective natural colour slates to provide maximum protection against UV. The presence of the slates provides a mechanical protection against light foot traffic and occasional maintenance as well as offering an aesthetic surface. It is an ideal membrane for roofing and exposed applications where it can be placed on top of the existing surface and providing an economical and efficient solution to leaking roofs.

Available in 2 finishing – Slated and Sand with thickness of 3mm in the size of 1 meter x 10 meter per roll.

One of the few popular choice for flat or low-sloped roofing applications where conventional shingles or other materials may not be suitable. This technique is commonly utilized in both commercial and residential construction able to apply different areas such as roofs, decks, balconies, and other surfaces from water damage. In addition, bitumen sheets torch on membrane have longer life spans than other conventional waterproofing methods if applied correctly. It is also ideal for properties located in areas with heavy rainfall or extreme weather conditions.

However the challenges of installing of bitumen torch-on waterproofing requires specialized equipment and skills, and should only be carried out by an experienced waterproofing contractor with expertise in torch-on roofing.

Conclusion

Both materials are specifically to prevent water to enter the substrate and having its own advantages and disadvantages. While torch on membranes offers highly durable and sturdier membrane hence having a longer life span, but it is not a seamless application where if not applied correctly would exposed to possible water penetration through its gap.

Liquid applied waterproofing membrane on the other hand is a seamless application, but may take longer time for application as it requires 2-3 layers of application with a curing time around 2-4 hours depending on the product. As liquid applied waterproofing is not as strong as bitumen sheet membrane, it is more prone to get damaged by external forces.

All in all, it depends on the pros and cons of each of these materials and taking in other factors such as area of application, the substrate and also the applicators experiences in handling these products.